Thrusters engaged: meet the team propelling ANU technology into space

It is 2am in Canberra on the second night of the new year. As Australia sleeps off festive celebrations, a group of physicists, engineers and space technologists are glued to the bright blue light of their computer screens.

They are watching a live stream from the other side of the world. A man is counting down in the official baritone voice of mission control. When he gets to one, a SpaceX rocket releases one last massive cloud of gas before lift-off.

Everyone watching is feeling a mixture of nerves and excitement, but they trust that as a team, they have done everything possible to ensure the journey from Cape Canaveral to low Earth orbit goes off without a hitch.

“The equipment that I spent a year building is now in orbit,” says ANU Technical Manager Dr Mahdi Davoodianidalik.

“It was amazing, exciting, and stressful at the same time because this was the first time we built something that was going into space.”

The SpaceX rocket may have been fuelled by a mix of kerosene and liquid oxygen, but the piece of ANU equipment it took with it was fuelled by something quite different. Aptly named the Bogong Thruster, it is propelled only by mothballs.

The Bogong Thruster formed part of the largest satellite stack that Australia has ever sent to space, and will be used to manoeuvre one of four mission satellites manufactured by Canberra-based company Skykraft.

“With the Bogong Thruster, you essentially have a box and fill it with naphthalene, mothballs,” says Professor Christine Charles, who leads the Space Plasma Power and Propulsion Group at ANU.

“When heated, the propellant goes directly from a solid to a gas. By emitting naphthalene gas into space, you create thrust, pushing your spacecraft forward in the opposite direction.”

Professor Charles has been working on and testing different spacecraft propulsion concepts for the past 20 years.

“Space is an emerging technology sector,” says Professor Charles. “Everyone is trying to develop propulsion systems based on different concepts. But this is the simplest concept, and we developed it here in the laboratory at ANU.”

After developing contacts within European and Japanese space agencies, she discovered that doing this type of work remotely has its challenges. The solution was working with the burgeoning space industry here in Australia. Enter Canberra-based start-ups Boswell Technologies and Skykraft.

“It’s wonderful because Skykraft are just five kilometres away,” she says. “And having financial and motivational support from Boswell Technologies means we can work much faster as we don’t have to go through the grant system.”

The low-tech simplicity of this new spacecraft propellant system, first developed by Dr Dimitrios Tsifakis as part of his PhD with Professors Charles and Boswell at the ANU Research School of Physics, is one of the reasons it has proved successful for commercialisation.

“Trying to sell high tech is not that easy,” says Boswell Technologies CEO Professor Rod Boswell. “There are a lot of things going on in Silicon Valley that fail.”

Professor Boswell says that this can be because buyers do not understand what the technology is. In comparison, the science behind the Bogong Thruster “can be understood by anyone in the pub”.

More than 200 Skykraft satellites are set to orbit the Earth. They will monitor global air traffic, helping to develop more efficient travel routes and to avoid mid-air collisions, and will also address gaps in surveillance and communications across remote areas.

The team are now working to make the technology even more appealing to industry.

“It’s wonderful that we now have a very robust thruster that can work in space,” says Professor Boswell. “Over the next few years, the Bogong Thruster will be included in a regular launch of satellites.”

Professor Boswell says that new versions of the Bogong Thruster will “improve performance by a factor of two or three, and perhaps fuel efficiency by two and a half times, making it a lot more cost-effective.”

After the noise and excitement of the moment of launch, the team continue to watch on in anticipation.

Aside from intermittent voices from SpaceX mission control, the live stream is now eerily quiet. After 87 minutes, the final payload is deployed, and the team hear what they have been waiting for: Skykraft separation confirmed.

Dr Davoodianidalik can now reflect on a job well done.

“When you see it detach from the SpaceX rocket and tumble into the darkness, that was really exciting for me.

“Now that it’s in orbit, we have a flight heritage, which means we can sell it to other companies and other companies will be happy to use it.”

For the newest space thruster on the market, the best is yet to come.

“It’s going to improve the footprint of Australia in space,” he says. “I’m proud that I helped towards this goal.”

The Bogong Thruster is designed and manufactured by researchers at The Australian National University and Boswell Technologies.

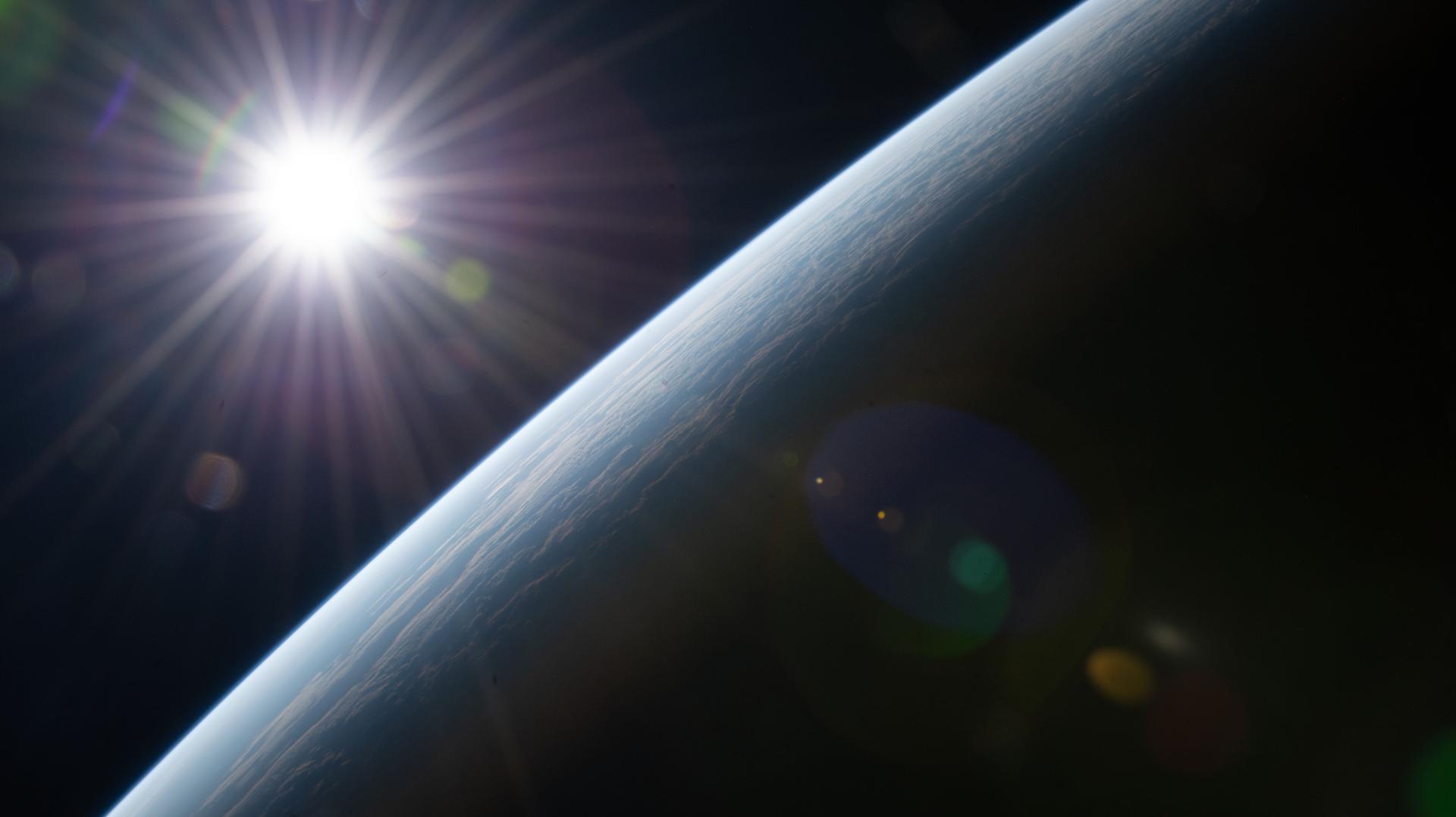

Top image: NASA. The sun's rays burst above Earth's horizon as the International Space Station orbited 264 miles above Western Australia on the coast of Shark Bay. 15 June 2022