What’s in storage for the future?

While scientists have not yet invented a flux capacitor to enable time travel, today’s capacitor is the fundamental building block of any gadget that you can imagine. However, capacitors on the market don’t really stack up to meet our modern needs. ANU researchers are partnering with one of the top manufacturers in China to develop a capacitor that could be a game changer.

Have you ever wondered why your laptop computer works well for a few years, but then starts to give up the ghost? The main culprit is the capacitor—when that fails, the laptop fails.

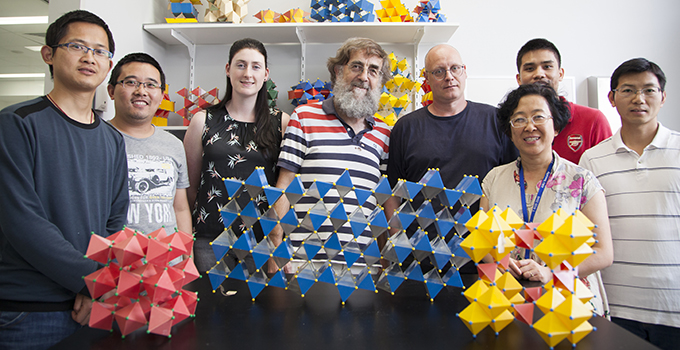

Professor Yun Liu’s research group, within the ANU Research School of Chemistry, is collaborating with Fenghua, one of the biggest capacitor manufacturers in China, to solve this problem by researching and developing the next-generation capacitor. As well as enhancing the performances and lifetimes of mobile phones, computers and other electronic devices, the new capacitor could be used for energy storage applications in power systems, including wind and solar.

So what exactly is a capacitor? It is an electrical component comprising two electrodes that are separated by a dielectric, which is an insulator that can store energy temporarily by becoming polarised. Two five cent coins and a piece of paper are all you need to make a capacitor.

Three parameters determine the performance of the insulation material: (1) its capacity to store large amounts of energy, which is determined by its dielectric constant; (2) its ability not to leak energy (low dielectric loss); and (3) its temperature stability. None of the capacitors on the market achieves all three.

High dielectric constant materials have high energy storage density. For instance, metals have an infinite dielectric constant due to the free migration of electrons, but their high conductivity means that they are useless as dielectric materials—much like a bucket with a hole in the bottom that’s meant to hold water. A dielectric material must be ‘watertight’, so plastic film, glass, paper, wood and other non-conductive materials can be used. Unfortunately, these materials have low energy storage capacity.

In 2009, Professor Liu and her colleague Professor Ray Withers began investigating a solution to the shortcomings of the humble capacitor. Using chemistry as a tool, they began to modify an inexpensive material called rutile, which is titanium dioxide. With tiny defects in the lattice of the rutile, it doesn’t lose the electric charge like a solid metal. Furthermore, the high dielectric constant material means that capacitors can be smaller and cheaper to manufacture, and can have a much longer lifetime due to less electrical fatigue. As rutile is a stable solid mineral, its dielectric properties are also very tolerant of high and low temperatures—ideal for industrial environments.

In 2013, Professor Liu and Professor Withers published their results in the prestigious journal Nature Materials. “I was excited from a scientific point of view, but I didn’t realise that our discovery was so attractive to industry,” says Professor Liu, who is an ARC Future Fellow. “After we published the paper, the ANU Office of Commercialisation put our patent on the ANU website. About a week later, we started to receive inquiries from consultants for the top manufacturers in the world.”

The collaboration with Fenghua provides Professor Liu’s research team the opportunity to translate its groundbreaking discoveries into technological innovations that will benefit society. Mobile phones, laptops and other gadgets will perform better and last longer, but Professor Liu is particularly excited about the prospects for new energy storage applications.

“Perhaps if we integrated 1000 capacitors, we could match the energy storage density of a lithium battery, but the power would be much higher. A lithium battery has a very high storage density, but the power is very low and the operating voltage is generally less than 5 volts. The capacitor is also solid state, so there are no toxic liquids—unlike the case of lithium batteries—to worry about either.”

Not only have Professor Liu and Professor Withers created a new field of research, they are also contributing to a new industry that could help society achieve a zero-emissions future.