Beating nature to make a night vision detector

Scientists have created new improved materials for detecting infrared light – the key to night vision. The new materials promise a more than tenfold improvement in efficiency over current night vision technology.

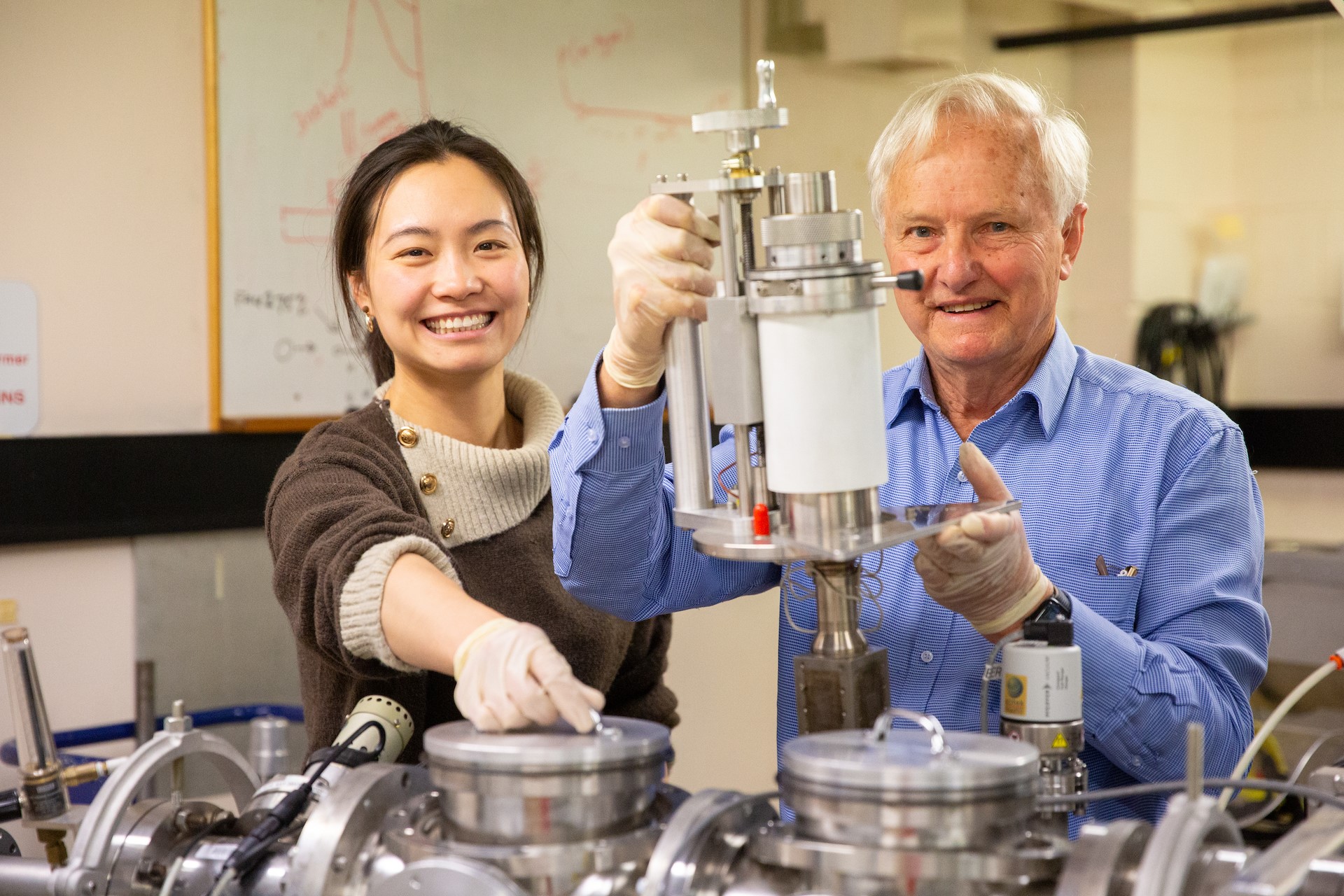

The challenge in creating these materials – made of germanium with tin atoms embedded in it – is beating nature, says Emeritus Professor Jim Williams, from the Materials Physics Department, and iiLab node of the Heavy Ion Accelerators (HIA).

“Nature wants the material system to relax to thermodynamic equilibrium. But if you can work under non-equilibrium conditions you can tailor the properties of materials in exciting ways,” Professor Williams says.

He and his international team have spent more than a decade devising non-equilibrium processes in the quest to make a semiconductor that, unlike pure silicon or germanium, can efficiently absorb infrared light.

Low efficiency is a major hurdle for night-vision technology - current technology is typically less than one per cent efficient. Additionally, it uses compound semiconductor materials that are problematic; the most promising of these materials, mercury cadmium telluride, is not particularly stable at room temperature and is not easy to integrate with silicon electronics.

In contrast, the team’s latest publications in the Journal of Applied Physics and the Journal of Vacuum Science and Technology herald a safe, stable and cheap infrared-sensitive material, which Professor Williams says should demonstrate well over one per cent efficiency.

Their success with tin-doped germanium has attracted the notice of the US Army and US Air Force, who have between them funded a string of grants, noting that “a prime reason for this collaboration is to access the unique ion implantation and ion beam analysis facilities at the ANU.”

An advantage of germanium is that it can be grown on silicon, which enables easy connection to conventional electronic circuitry.

The challenge has been getting the tin to stay embedded in the germanium. At thermal equilibrium the maximum amount of tin that will stay dissolved is only one per cent, which is not enough to shift germanium’s absorption window from its natural near-infrared region (wavelengths shorter than 1.5 microns) to mid infrared (around 4 microns). This needs tin content above ten per cent.

But the team found that level of concentration, if allowed to come to thermal equilibrium, results in tin separating and pooling on the surface like oil on water.

To trap it in place, they use two methods. One is to deposit a layer of the mixture from a chemical vapour, below 300 degrees, to suppress equilibration. But this method results in material that is quite defective. The second way, unique to the team, is to implant tin ions into the germanium at cryogenic temperatures. This has the side effect of damaging the germanium crystal, but it can be healed with flashes of laser light that momentarily melt the top layer, allowing it to re-crystallise with much fewer defects.

Analysis showed both fabrication techniques result in material defects – but quite different defect types and amounts.

So, the ideal method looks to be a hybrid, starting with chemical vapour deposition, and finishing off with icing made from an ion-implanted, laser-melted layer. Using this approach, the team has achieved low defect-density material with over ten per cent tin.

The development of this hybrid approach to fabrication is a direct result of the team’s opportunities to explore and select the most appropriate nanofabrication techniques from a wide range of options in the local area. Between HIA and the node of the Australian National Fabrication Facility in the Research School of Physics, the researchers have access to ion implantation, thin-film deposition and etching, thermal processing, and photo- and electron-beam lithography.

As well as fabrication techniques, the locale boasts many analysis options, including at the node of Microscopy Australia in the John Curtin School of Medicine: Rutherford backscattering and channelling, cross-sectional electron microscopy, Raman spectroscopy, atomic force microscopy and X-Ray diffraction.

“It’s a unique and comprehensive package; the whole is much greater than the sum of the parts,” said Professor Rob Elliman, Director of iiLab.

The potential for practical devices excites team member Dr Xingshuo Huang.

“It’s amazing that we have taken the process from fundamental research of germanium-tin alloys to finally making photodetectors out of them," she said.

“These photodetectors can be applied to a wide range of studies, including environmental and life sensing fields.”

This article was first published by ANU Research School of Physics.