ANU helps make protective equipment for health workers

The Australian National University (ANU) is helping to ensure health workers have adequate supplies of personal protective equipment (PPE) amid the coronavirus pandemic, by coordinating the production of thousands of face shields and masks.

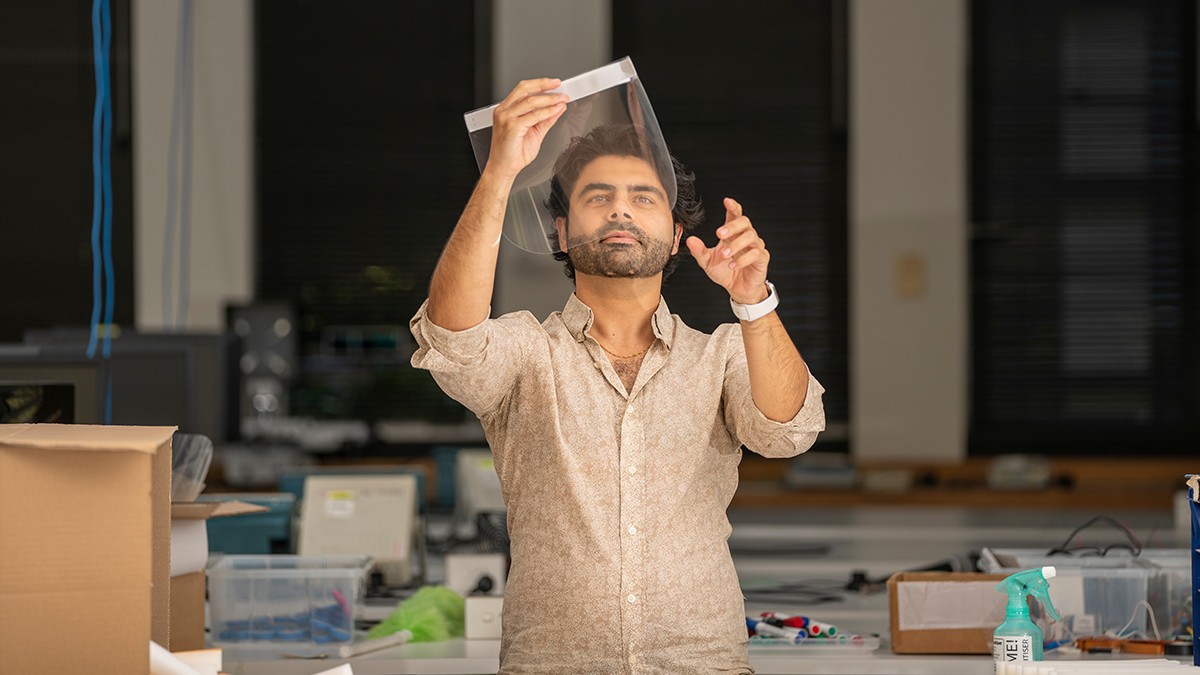

The ANU MakerSpace has produced 2,000 face shields, and is preparing to make another 15,000 as required.

They have also created a prototype face mask that volunteers are sewing and returning to ANU to be sterilised and made ready for use by people working in non-frontline health services, such as pathology labs. They have enough volunteers and materials to make about 2,000 face masks.

Dr John Debs, who is the founder of the MakerSpace, said the PPE would be provided to health workers in the ACT and NSW free of charge.

“We see this as a community good from the University to supplement the usual supply chain of hospitals, general practices and other frontline health services,” said Dr Debs from the ANU Research School of Physics.

“We had heard buzz around people 3D printing face shields but, after looking at the designs, we knew we could make them faster and more effectively with other tools. We found some open-source designs from the United States, and we ran with them as a starting point.”

ANU MakerSpace is working closely with ACT Health and NSW Health to provide face shields.

“The healthcare community has responded very positively to our face shields, and they have had some input into the design,” Dr Deb said.

The ANU team reached out to ACT Health through a former ANU Medical School student and member of the MakerSpace.

“That really started things to get us to where we are now, as well as other connections our community made into the health system,” Dr Debs said.

The ANU MakerSpace, which has 1,400 members including students, academics and professional staff from various disciplines, is an initiative founded and led by the Research School of Physics, and joined by both the School of Art and Design and the Research School Electrical, Energy and Materials Engineering at ANU.

ANU MakerSpace is a community facility where people “can learn by doing” to support their research, education or personal interest.

Rachael Hanrick, the MakerSpace staff member managing the PPE effort, said artists, craftspeople and designers from the ANU School of Art and Design have provided critical expertise to the project.

“These people are all makers and doers, and their hands-on making experience and material knowledge are invaluable in our MakerSpace community and for this project in particular,” said Ms Hanrick, who is a mechanical engineer, has trained as a fine-furniture maker and is undertaking a Master of Design at the ANU School of Art and Design.

“We did not reinvent the wheel – we built on design work that had already been done in other parts of the world hit harder and faster by COVID-19 than Australia has been so far. Our strength lies in the speed with which we can go from an idea to production, drawing on the strong networks and agile nature of our makerspace,” she said.

According to Ms Hanrick, making is a fundamental human activity, and its importance in educational and vocational settings cannot be understated.

“Modern makerspaces are in many ways a continuation of shared making communities that have existed for centuries – examples ranging from woodworking guilds, quilting circles, Men’s Sheds, hackerspaces and R&D labs,” Ms Hanrick said.

“While technologies such as 3D printers and laser cutters are more accessible than ever, they are still limited to relatively affluent makers – makerspaces fill this void as communal spaces that give access to a shared pool of resources.”